Optimal loading

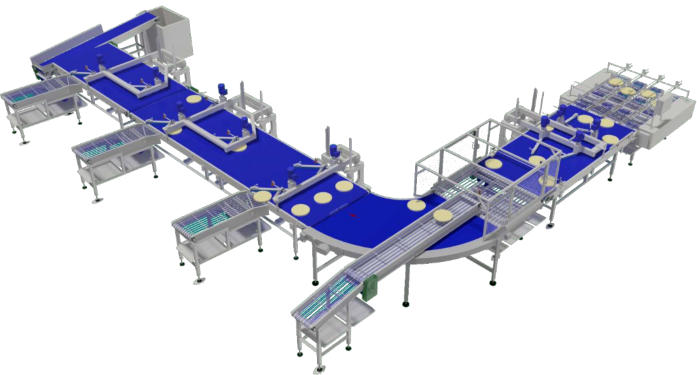

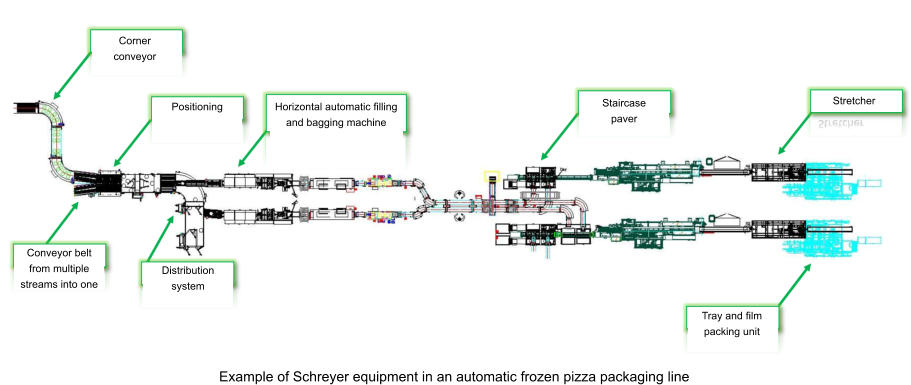

Intelligent transport systems enable optimum organisation of production processes. A parallel, fully redundant production line, which is kept in a state of readiness, can be switched on at a moment's notice. Production line in a state of readiness, backed up by a fully redundant production line. In order to ensure optimum utilisation of the cold storage room at all times, piece-by-piece separation and distribution takes place depending on the production process. Special distribution systems ensure efficient cooling gas consumption while preventing products from freezing to one another - at constantly increasing capacities!A wide range of possibilities

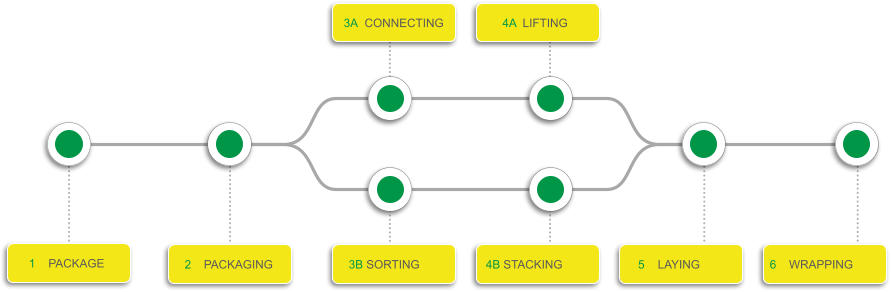

Whether sorting and orderly stacking, stacking, lifting, distributing, bundling, packing or all operations at once - with Schreyer you have a complete one-stop-shop solution at your fingertips. You get a complete solution from a single source when you work with Schreyer. Shrink or stretch? We know how to do both. Thanks to the careful sequencing of operations, we are able to achieve extremely precise results in process development.Automatic vertical buffer creation system

Schreyer Sondermaschienen GmbH

is designed to equalise the production flow in order to achieve smooth flow to the next packaging operation;

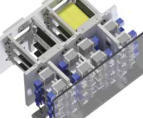

Electropneumatic high-speed sorting line

Schreyer Sondermaschienen GmbH

- Up to 500 items/min capacity - Gentle transfer by spreading the product onto several conveyor belts (2 to 9) with piece-by- piece movement in relation to one another - Applications: High-speed filling processes requiring non-stop, touch-free bagging - Hygienic design

Spesial - purpose

machines

Transportation from the freezer

Schreyer Sondermaschienen GmbH

- ET12/16 sorter; - distribution to the appropriate plastic bagging machines

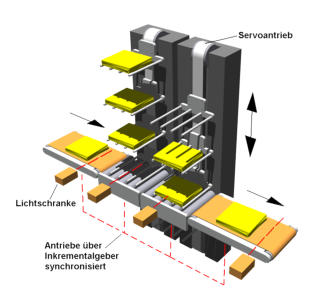

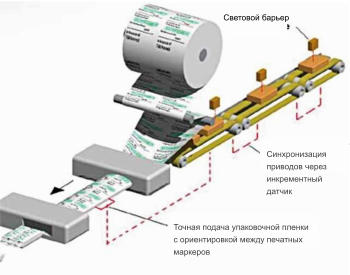

Filling machine (90° feed option)

Schreyer Sondermaschienen GmbH

- For fresh products with delicate consistency, filling without product grip - Fully automatic packing without soiling the sealing lip - The process is suitable for the operation cycle of low grip packaging machines - Synchronization of drives via incremental encoder - The dispenser is used in processes that do not allow personnel to come into contact with the product for hygienic reasons (affects shelf life)

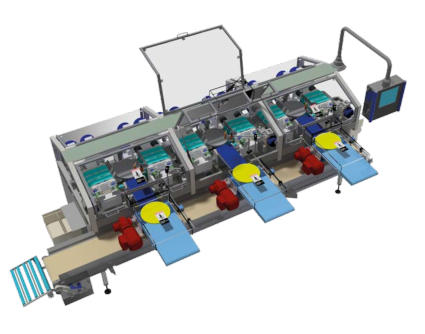

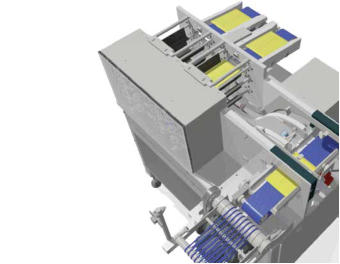

Automatic stacker (gantry robot version)

Schreyer Sondermaschienen GmbH

- Gentle stacking of heavy products - Fully automatic process - Process synchronisation in sync with the operation of the packaging machines with low insertion force - Hygienic design for applications in moist environments - Option: distribution of pieces of cheese before placing

Automatic box shaper

Schreyer Sondermaschienen GmbH

- box forming - for all formats by the use of different dies

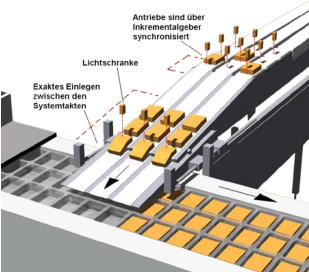

Automatic step-laying machine

Schreyer Sondermaschienen GmbH

- High speed servo paver - Fully automated paving process - Patented damping system - Multistage bridging system - Synchronised sequence of operations - Gentle product placement - Compact design - Robust damping system

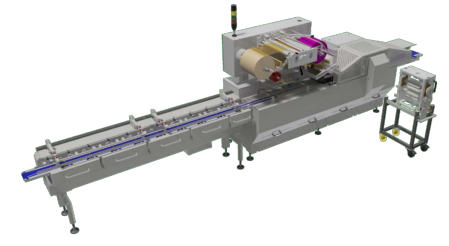

Horizontal Bagging machine

Schreyer Sondermaschienen GmbH

- film wrapping

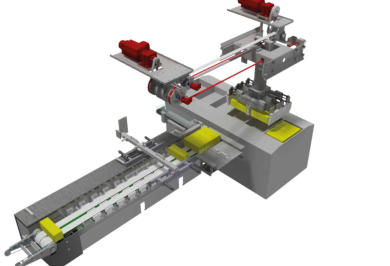

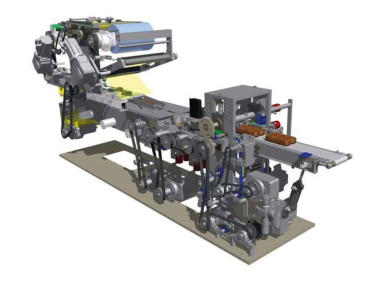

Wrapping machine and tensioner

Schreyer Sondermaschienen GmbH

- 35 rpm (single and twin drum) - Quick retooling - Shorter cutting lengths due to parallel machining - Use of servo motors for all drive units - Carton packaging as an option to film packaging - Space saving machine thanks to parallel machining parallel processing - Quick changeover between different packing sizes - Precise coordination of movements due to application of servo drives - Twin feed line for high speed systems

Sorting automated line

Schreyer Sondermaschienen GmbH

- Capacity up to 20 cycles/min. - Gentle piece-by-piece distribution due to synchronous spreading belts conveyor belts - Sorting by piece-by-piece skewing of products - Microprocessor-controlled synchronisation of cycles - Applications: High-capacity processes for piece-by-piece Applications: Processes with high throughputs for piecewise processing of products with delicate consistency

Uninterrupted damping system

Schreyer Sondermaschienen GmbH

- The mechanical principle of the paver is based on the effect of magnets, which eliminates the use of rubbing surfaces and ensures the paver's mechanical principle is based on the interaction of magnets. The unit has a compact design and can be integrated into the line without significant footprint.

Synchroniser (using a bagging machine as an example)

Schreyer Sondermaschienen GmbH

- Floating synchronisation without touching the product for gentle handling - Suitable for all bagging or carton packaging equipment - Flow rates up to 300 pieces/minute - Microprocessor control

Automatic bagging machine

Schreyer Sondermaschienen GmbH

- Up to 500 pieces/min capacity - Floating synchroniser without product touch - Microprocessor based film synchronisation with cross sectional compaction length and cross sectional sealing with S7 control unit - Thin film capacity due to individual drive of each feed roller - Automatic error correction through folding sheet at the machine outlet

Film reel packer

Schreyer Sondermaschienen GmbH

- Up to 240 pieces/min. - Optimum grouping due to multi-position system with 16 fully synchronised drives (ProfiBus) - Economical film consumption thanks to single drives - Format selection via Siemens operation panel 3 to 10 product types - Including open folding box control - Optional label dispenser or Easy-Open-System

Electropneumatic high-speed

sorting line

Schreyer

Sondermaschienen GmbH

- Up to 500 items/min capacity - Gentle transfer by spreading the product onto several conveyor belts (2 to 9) with piece-by-piece movement in relation to one another - Applications: High-speed filling processes requiring non-stop, touch-free bagging - Hygienic designOptimal loading

Intelligent transport systems enable optimum organisation of production processes. A parallel, fully redundant production line, which is kept in a state of readiness, can be switched on at a moment's notice. Production line in a state of readiness, backed up by a fully redundant production line. In order to ensure optimum utilisation of the cold storage room at all times, piece-by-piece separation and distribution takes place depending on the production process. Special distribution systems ensure efficient cooling gas consumption while preventing products from freezing to one another - at constantly increasing capacities!

Heading Text

A wide range of possibilities

Whether sorting and orderly stacking, stacking, lifting, distributing, bundling, packing or all operations at once - with Schreyer you have a complete one-stop-shop solution at your fingertips. You get a complete solution from a single source when you work with Schreyer. Shrink or stretch? We know how to do both. Thanks to the careful sequencing of operations, we are able to achieve extremely precise results in process development.

LONG HEADING TEXT

0091/28190221

Dolor proident aute lorem laboris

cillum! Cupidatat incididunt.

Schmitt

LONG HEADING TEXT

Consectetur velit qui tempor veniam cupidatat minim nulla pariatur ad in dolor et dolor ea sed enim. In adipisicing quis sit ex velit lorem. Ut nostrud voluptate in ipsum deserunt adipisicing duis non anim in. Voluptate tempor ut. Nisi ipsum, consequat velit laboris ea. Reprehenderit ea id. Dolore laboris ut qui amet? Sunt est sit consequat adipisicing commodo elit anim.

Ursa TS

- Pos 1

- index-en

- index-de

- jbt tipper tie-ru

- jbt tipper tie-de

- jbt tipper tie-en

- jbt schroeder-ru

- jbt schroeder-de

- jbt schroeder-en

- jbt consumables-ru

- jbt consumables-de

- jbt consumables-en

- schreyer-ru

- schreyer-de

- schreyer-en

- Kutter Alpina Swooper SWV200-S

- Kutter KuG Wetter 120 STL

- Kolbenfuehler REX RKF130

- Doppelclipautomat TT18-15

- Poekelinjector Schroeder IMAX 300SL

- impressum-ru

- impressum-de

- impressum-en

- datenschutz-ru

- datenschutz-de

- datenschutz-en